LSG Low Smoke Generator Trouble Shooting Using A G300

How to set up and run a Low Smoke Generator (LSG) using a G300 fogger:

1: Place the machine on a level surface and ensure that it will not roll.

2: Connect the blue Twist-lock connector from the LSG to the custom port on the rear panel of the G300

3: Position the front of the G300 directly against the foam ring on the inside of the LSG unit.

4: Turn on the G300 and ensure that it is in “G300” mode*, which is indicated by a flashing “G” in the “Ready Flash” window of the remote display.

5: Turn the “Interval” control dial completely clockwise until “DEL” appears on the display.

6: Adjust the “Duration” control dial until desired delay is displayed. The correct delay is One second for every Three feet of CO2 hose.

7: Adjust the “Flow Rate” to change fog output level. It is recommended to start at a lower setting and adjust from there.

8: Connect the CO2 supply hose to the "Liquid" valve of the CO2 tank. Using a wrench, ensure that the connection is snug. Fiber washers are necessary to prevent leaks and are available from gas suppliers, and from Roger George Rentals.

9: Place the Fog Fluid tube into a bottle of Molecular fog fluid

10: Ensure that there is sufficient pressure inside the tank. The pressure inside the CO2 tank MUST be between 300psi and 340psi for the machine to operate. Each CO2 tank is equipped with a “Pressure Builder” valve that, when turned Counter Clockwise, builds pressure inside the tank.

11: On the tank, open the “Liquid” valve fully by turning it Counter Clockwise.

12: When the G300 has had sufficient time to heat up (indicated by 3 flashing lines dissapearing) turn on the “Smoke” button. The CO2 will activate first and then, after the delay, fog will begin coming from the front of the machine. *To switch to “G300” mode: This method is for Roger George Rentals’ G300 machines that are equipped with a key-switch to prevent accidental mode changed: i: Ensure the power is turned off ii: Turn the key-switch to the “G300” mode position iii: Turn on the main power iv: The display should change to read “G300” This method is for machines that are NOT equipped with a key-switch but have a “G300” button: i: Turn OFF the machine ii: Hold down the G300 button and turn ON the machine. iii: After a short period, the display will change to read “G300” and will continue with the start-up procedure. You can now release the button.

How to break down setup (cleanup):

1: When you are finished using the LSG, turn off the fog from the G300 unit, DO NOT POWER OFF THE MACHINE. 2: On the CO2 tank, turn the “Liquid” valve all the way off. 3: Turn on the fog from the G300 machine to purge the line of CO2. 4: When you are certain that the CO2 has been purged from the line, turn off the fog, and disconnect the CO2 line from the LSG. 5: Turn off the main power on the G300 machine and disconnect the power cable for the entire unit. It is now safe to disconnect any cables and remove the fluid from the machine.Notes:

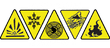

Do not tamper with CO2 tanks! It is crucial for the CO2 tanks to be able to vent if the pressure gets too high. There is a safety valve located on the top of all Roger George Rentals CO2 tanks. Periodically, the tank may de-pressurize violently. It is advised that you keep the tanks away from people because CO2 snow (dry ice) is often expelled during this process. Be aware that the de-pressurization process is loud and can cause temporary hearing loss as well as ruined filming/sound recording. Warning! The CO2 (carbon dioxide) used in LSG machines is extremely cold! Avoid direct contact with CO2 at all times. Contact with CO2, in both liquid and solid form, can cause frostbite in a matter of seconds! Take precautions and be aware of both your surroundings and your machines. Be aware that using cryogenic foggers might create water vapor that settles on the ground and could create slip-and-fall hazards. This effect is especially apparent if no ducting is used and the fog comes directly from the mouth of the unit, in this case, be aware that the area immediately under the mouth will become wet and slick. To help prevent hazards, keep some towels or packing blankets nearby to keep the water on the ground to a minimum. If a machine is run in a small environment for a long period of time, the floor and other surfaces will become wet. Be aware that the use of most Cryogenic fog methods can displace the oxygen in a room (rather quickly with some of the larger setups.) Be aware that cryogenic fogs are heavier than oxygen and as a room begins to fill with fog, it may become harder to breathe. Ensure that a room is never completely filled with fog if a person is present, and be aware that dropping below the fog level (either crouching, laying on the floor, or purposefully raising the fog level to above your head) is not advised because it can cause dizziness, oxygen deprivation, and, in extreme cases, asphyxiation.

Frequently Asked Questions:

Q: Is it safe to inhale fog/smoke? A: All of the fluids we use at Roger George are non-toxic; however, it is very common for atmospheric effects to irritate people's respiratory systems. Everyone handles smoke/fog differently, some people can be immersed in the densest fog for hours without even a cough, while others are easily irritated by the lightest of hazes. It is impossible to tell how you or your crew will react to the different fog/smoke effects until exposure occurs. Be aware that the LSG unit has additional hazards that other fog machines do not: because the LSG creates low-lying fog that is laden with CO2, asphyxiation is a dangerous possibility! Never lay down in the fog or allow the fog to go raise above shoulder-level, this will ensure that you are still able to breathe oxygen and that you will not suffocate. Q: The LSG is not producing ground-fog, instead, it is simply rising into the air. What’s wrong? A: There could be a number of problems here. First, check that you are using the correct fog fluid. You should always use LeMaitre Molecular Fluid when running an LSG. Check to make sure that the CO2 tank is connected properly. Check the gauge on the tank and ensure that there is at least 300 psi of pressure inside. If there is not enough pressure, turn the “Pressure Builder” valve all the way counter clockwise and wait for the pressure to reach 300 psi. Check and make sure that the hose is connected to the “Liquid” valve on the tank. Check the “Duration” dial on the machine. If this dial is set incorrectly, the machine might be taking in CO2 gas instead of liquid and won’t provide sufficient cooling. Look at Step 6 above to determine how to properly set the duration/delay. Q: My G300 is stuck in haze mode! How do I get it into G300 mode? A: There are 2 methods for switching the machine into G300 mode (depending on which machine type you have) The first method is for machines that have a “G300” button located at the top of the control panel. Make sure the machine is off. Turn on the machine and hold down the “G300” button. After a brief period, you should see “G300” on the screen and the machine will continue with its startup sequence. You can now let go of the button, and the machine will be in “G300 Mode.” The second method is for machines that have been modified and have a silver key-switch that says “G300” Make sure the machine is off and turn the key-switch to the “G300” setting. When you turn the machine on, it should now be in “G300 Mode.” Q: I can’t disconnect the hose from my CO2 tank; any suggestions? A: First, make sure you have purged the line and that there is no pressure in the hose. Pressure can make it difficult to loosen the fitting and could also be dangerous because when the hose is disconnected while still pressurized, cold CO2 can be released and cause frostbite. If the fitting on the end of the hose is extremely cold, it can “lock” itself to the tank and become difficult to remove. Allow the fitting to sit for a few moments so it warms up, and then try again with a tight-fitting wrench. This is a common problem that usually happens to machines that have been running for a long time. To prevent the need to over-tighten the fitting during setup, ensure that you are using the correct fiber washers. These washers prevent leaks and make it so you don’t have to crank down on the fitting just to get it air-tight. Remember, it just needs to be snug.

Looking for more information about Fog Machines and Hazers? Visit our fog and haze look post.

Hi there. I woek ib special effects in the uk and something im trying to find out is how to make outdoor low lying smome on a large scale without using dry ice.

Preferably im lookong for a afluid that id be able to put into an outdoor gas powered smoke machine. Thanks

I want details of low smoke for prooffetionals

Leave a comment